|

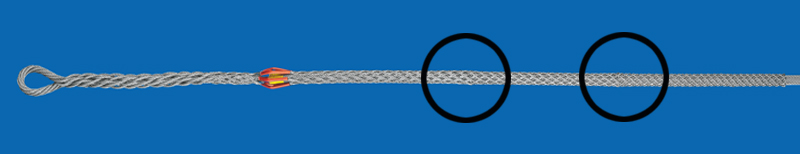

In contrast to ground and underground laying of cables, with the pulling of overhead lines the traction forces that develop and that have to be borne by the overhead cable pulling grips are considerably larger. For this reason, much stronger cords and a triple strand mesh are required. However, in order to keep the overhead cable pulling grips flexible, the netting is composed of three different mesh types that exactly correspond to the occurring distribution of traction forces:

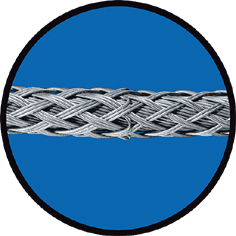

| Type 1: single-strand netting - | for the bearing of moderate loads and for the build-up of force closure |

| Type 2: double-strand netting - | for the bearing of higher loads and for further build-up of force closure

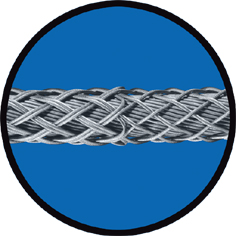

| | Type 3: triple-strand netting - | for the bearing of the full loads and for complete force closure

|

Through the resulting self-interlacing effect the pulling grip maintains a high traction with the conductor cable.

This pulling grip comes with a hand-spliced loop that allows for pulling the grips over driving pulleys, capstan heads and figure-of-eight breakers due to its high flexibility.

Random samples of these pulling grips are handed over to an independent rope testing shop for the execution of rupture tests. On request, we are happy to provide our customers with a manual (compiled according to our practical experience) as well as a table containing all technical data for pulling grips for overhead cables upon delivery of the products.

|

Designation

|

Rope-

Diameter

[mm]

|

Colour-

coding

|

Permissible workload with a 3 times higher security load [kN]

|

Mesh length

approx. [mm]

|

Total length Dimension

approx. [mm]

|

MSP 10,9 |

6 - 10,9 |

violet |

6 |

770 |

1100 |

MSP 15,9 |

11 - 15,9 |

green |

12 |

900 |

1380 |

MSP 20,9 |

16 - 20,9 |

yellow |

22 |

1180 |

1690 |

MSP 26,9 |

21 - 26,9 |

grey |

31 |

1550 |

2200 |

MSP 37,9 |

27 - 37,9 |

red |

40 |

1650 |

2440 |

MSP 44,9 |

38 - 44,9 |

brown |

42 |

1850 |

2600 |

MSP 55 |

45 - 55 |

blue |

46 |

2400 |

3400 |

|